An Establishment Inspection Report is created after FDA investigators inspect facilities involved in manufacturing, processing, or distributing FDA-regulated products.

More than just a summary, the EIR is a critical tool used by both the FDA and regulated entities to assess compliance, address operational risks, and implement meaningful improvements.

In this article, we’ll explain everything you need to know about the EIR, its key components, why it matters, common challenges organizations face, and the regulatory framework it operates within.

What Is an EIR?

An Establishment Inspection Report (EIR) is an official FDA document summarizing an inspection’s scope, key findings, and potential violations. It is prepared within 30 working days after the inspection, following the issuance of Form FDA 483.

Once completed, the EIR is reviewed by the FDA’s District Office or relevant Center, which then assigns an official inspection classification.

- NAI (No Action Indicated): There are no objectionable items or practices found during the inspection.

- VAI (Voluntary Action Indicated): Objectionable items were observed, but they do not meet the threshold for regulatory action.

- OAI (Official Action Indicated): Major violations were identified, and the FDA will likely take further regulatory actions, such as issuing a warning letter.

The EIR not only documents the findings but also provides critical context around inspection decisions. This serves as an essential tool for both the agency and the inspected firm to assess and improve compliance efforts.

Why the FDA EIR Matters

The EIR is far more than a routine document. It carries important consequences for your organization.

- Regulatory Standing: An EIR with significant findings may result in Warning Letters, import alerts, or additional oversight.

- Operational Guidance: Companies use EIRs to identify weaknesses in their quality systems and improve internal processes.

- Risk Management: Understanding what FDA inspectors are focusing on helps companies allocate resources and prioritize improvements.

- Audit Preparedness: EIRs often highlight systemic issues that may be reviewed again in future inspections.

To fully understand the impact of the EIR, it’s essential to look at the regulatory framework that defines how inspections are conducted and how findings are evaluated.

Key Regulations Guiding EIR Assessments

To understand the significance of an EIR, it’s important to recognize the regulatory framework that governs FDA inspections.

- Federal Food, Drug, and Cosmetic (FD&C) Act: This foundational law authorizes the FDA to oversee the safety of food, drugs, and cosmetics in the United States.

- 21 CFR Parts 210–211: These regulations cover the current Good Manufacturing Practice (cGMP) requirements for manufacturing, processing, packing, or holding drugs.

- 21 CFR Part 820: This part outlines the Quality System Regulation (QSR) for medical devices, providing guidelines for design, production, and distribution controls.

These regulatory bodies and standards provide important context for interpreting the key components included in every Establishment Inspection Report. They help define what inspectors look for during evaluations and shape how compliance is assessed and documented.

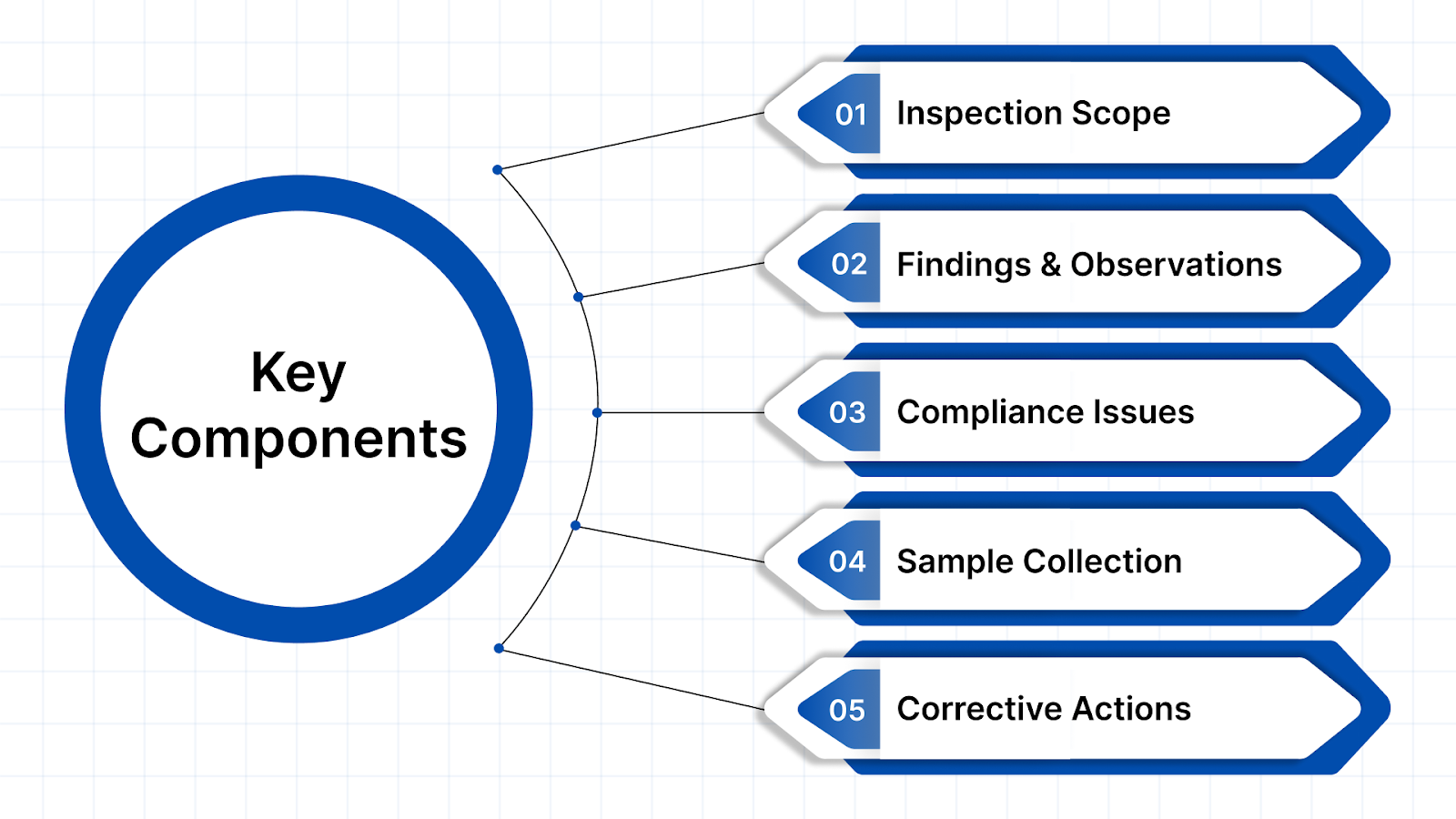

5 Key Components of an Establishment Inspection Report

An EIR is organized into specific sections that provide a clear view of inspection findings. These usually include.

1. Inspection Scope and Context

This section outlines the purpose and scope of the inspection, including routine, for-cause, or follow-up inspections. It provides a snapshot of the systems evaluated (e.g., Quality, Production, Laboratory Controls) and offers insight into the inspector’s focus areas. Your FDA readiness team can assess if any documents fall outside those typically requested during inspections and ensure they are properly prepared in advance.

2. Observations and Findings

Often linked to Form FDA 483, this section describes any non-conformances noted during the inspection. It frequently references specific CFR citations and explains where procedures fell short of regulatory expectations.

3. Identifying Potential Compliance Issues

The EIR highlights any problematic practices or potential regulatory violations that must be addressed before the next inspection to prevent further penalties or citations. If these issues remain unresolved, they are likely to appear again on the next Form FDA 483. Proactively correcting deficiencies or areas of concern noted in the EIR helps companies reduce the risk of serious regulatory actions.

4. Details on Sample Collection

When the FDA collects samples during an inspection, such as product samples or raw materials, the EIR explains the reasons behind the collection. This information helps assess any potential concerns regarding product quality or safety. A large number of samples may indicate underlying issues, so it’s important to address similar problems within your facility promptly.

5. Corrective Actions and Recommendations

The EIR typically highlights whether the FDA recommends further actions, such as warning letters, import alerts, or follow-up inspections. This information helps the company understand the severity of the issues and the steps needed to prevent more serious consequences. It’s important to address any similar or potential problems within your organization promptly.

By reviewing these core elements of an EIR, organizations gain a clearer understanding of where their compliance systems may fall short and what corrective actions are expected.

Responding to EIR and Form FDA 483

Once your organization receives an Establishment Inspection Report (EIR) and Form FDA 483, it’s essential to respond promptly and effectively to ensure continued compliance and avoid more severe regulatory consequences.

1. Understand the Findings

The first step is to carefully review the Form FDA 483 observations and the EIR’s inspection classifications (NAI, VAI, OAI). Each observation on the 483 will indicate specific areas of non-compliance, ranging from minor deficiencies (VAI) to major violations (OAI). Understanding the severity of each finding helps in prioritizing corrective actions.

2. Develop a Corrective and Preventive Action (CAPA) Plan

For each observation listed on Form FDA 483, your company should develop a Corrective and Preventive Action (CAPA) plan.

This plan should:

- Address the root cause of each issue

- Include detailed steps for correcting the deficiency

- Outline preventive measures to ensure similar issues do not recur

Make sure the plan is specific, actionable, and documented. The FDA will review this plan to ensure its adequacy.

3. Communicate with the FDA

Responding to Form FDA 483 is a formal process. Companies are required to submit a written response within 15 business days. In this response, you should:

- Acknowledge the findings

- Provide an overview of your corrective actions

- Offer timelines for implementation

- Demonstrate a commitment to compliance and continuous improvement

If necessary, follow up with the FDA to clarify any questions or concerns about the actions you’re taking.

4. Implement Changes

Once your corrective actions are finalized, implement them without delay. This may involve updating procedures, enhancing employee training, revising documentation, or improving facility conditions. Ensuring that these changes are carried out properly and consistently is crucial to demonstrate compliance.

5. Follow-Up Inspections

After responding to the FDA 483 and EIR, the FDA may conduct a follow-up inspection to assess whether the corrective actions have been successfully implemented. It’s essential to maintain an inspection-ready environment and show ongoing commitment to regulatory compliance.

Also read: Effective FDA Form 483 Response Strategies

Compliance Challenges Affecting EIR Outcomes

FDA inspection trends reveal several recurring issues that organizations must proactively address.

1. Timeliness of EIR Issuance

Delays in the completion and issuance of the EIR can affect an organization’s ability to address compliance gaps promptly. Staffing limitations at the FDA often contribute to extended review times, leaving companies uncertain about how to proceed.

2. Adapting to Digital Transformation

With the FDA incorporating AI-powered analytics into its inspection process, companies need to ensure their compliance systems are aligned with these technologies. Failure to do so could lead to delays or discrepancies in how findings are interpreted and reported.

3. Global Coordination and Harmonization

As global regulatory bodies, such as the EMA, work towards harmonizing inspection standards, companies with operations in multiple regions may face challenges in aligning their practices with both FDA and international regulations, affecting overall compliance and inspection outcomes.

By proactively identifying potential issues and strengthening your internal processes, you can minimize risks and respond confidently when inspections occur.

How to Prepare for EIRs More Effectively?

Preparing for an EIR starts long before the inspection begins. A proactive approach helps ensure your systems, documentation, and personnel are always inspection-ready. Here’s how you can improve your approach.

1. Conduct Mock Inspections

- Action: Schedule quarterly or bi-annual mock inspections to simulate real FDA scenarios.

- Goal: Identify potential gaps in your processes, documentation, and personnel preparedness.

- Impact: Mock inspections will help your team practice real-time responses, assess how well SOPs are followed, and evaluate overall facility conditions. They also reinforce a culture of readiness and continuous improvement, ensuring that your team remains confident and prepared under inspection pressure.

2. Address Historical EIRs

- Action: Review historical EIRs from your facility and industry peers to identify common inspection issues and trends.

- Goal: Uncover recurring patterns in inspection findings and address frequent compliance gaps.

- Impact: By proactively addressing these common trends and known industry issues, you can implement preventive measures to avoid similar findings during your next inspection. This enables you to stay ahead of potential risks, improving the likelihood of a favorable inspection outcome.

3. Centralize Documentation

- Action: Centralize all compliance records (SOPs, CAPAs, training logs, batch records, etc.) into a single, easy-to-access system.

- Goal: Ensure quick, efficient access to critical documents during the inspection.

- Impact: A well-organized document repository reduces delays during the inspection process and demonstrates organizational control and maturity to the FDA. It ensures that nothing is overlooked and speeds up the overall inspection and follow-up processes.

4. Utilizing Technology

- Action: Adopt digital tools to streamline your audit preparation, risk assessments, and ongoing compliance management.

- Goal: Enhance visibility into compliance status and identify areas for improvement more effectively.

- Impact: Technology like AI-powered platforms can improve the efficiency of your internal audits, provide real-time updates, and enhance risk prediction. By automating and optimizing these processes, you save valuable time, reduce manual errors, and stay prepared for inspections at all times.

Digital tools help streamline audit preparation and risk assessment processes. One such platform is Atlas Compliance.

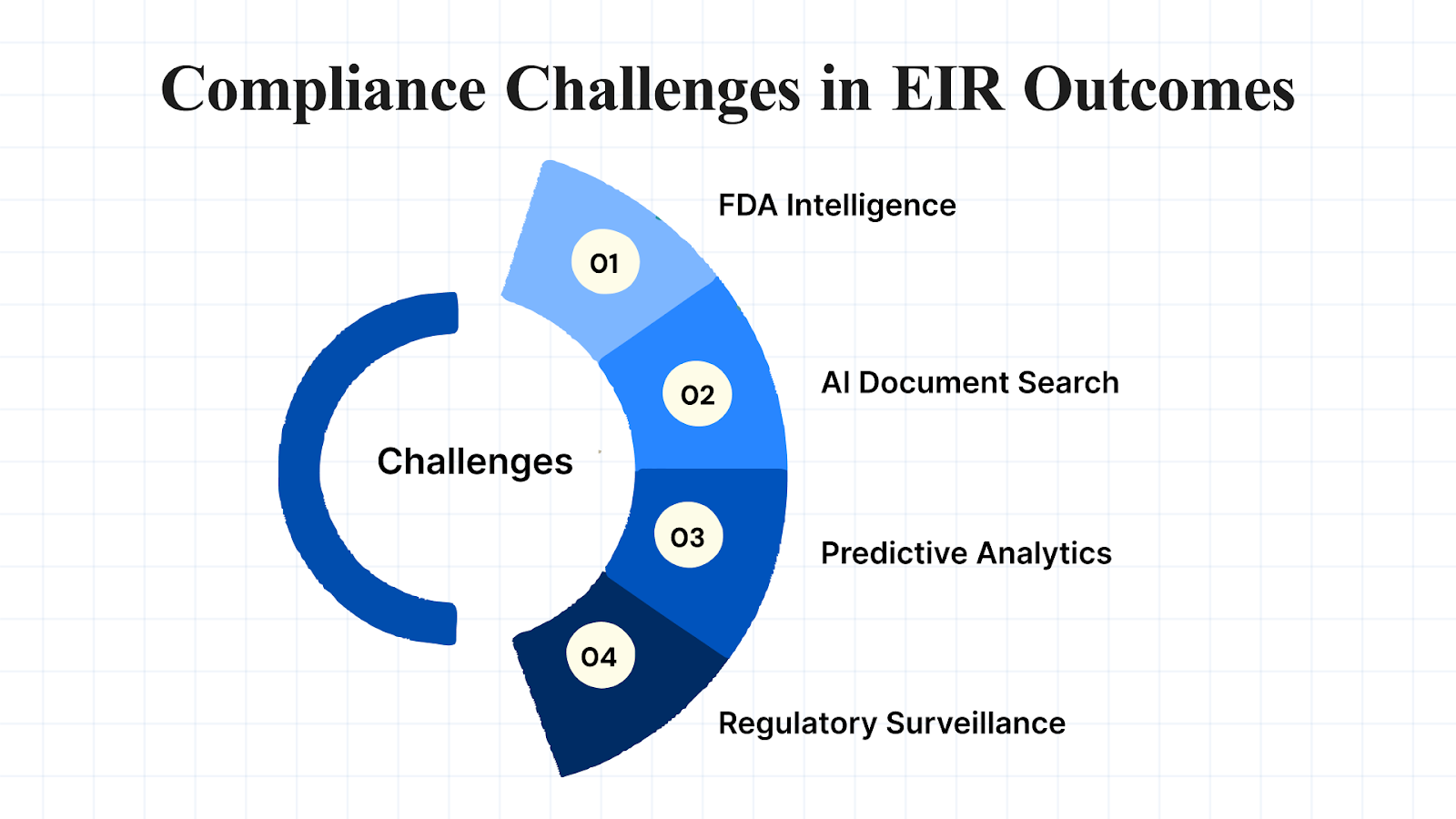

How does Atlas Compliance Support Effective Inspection Preparation?

Atlas Compliance centralizes inspection tracking, regulatory updates, and audit preparation, enabling companies to stay informed and consistently ready for inspections. Here’s how they help.

- FDA Inspection Intelligence: Access a comprehensive, searchable database of FDA inspection reports, including Form 483s, warning letters, and CFR citations to benchmark performance and prepare proactively. This insight highlights common compliance issues, enabling companies to address them before future inspections.

- AI-Powered Document Search: Atlas uses advanced Natural Language Processing (NLP) to efficiently locate critical information within extensive document collections, ensuring precision even under tight deadlines.

- Predictive Compliance Analytics: Atlas uses historical inspection data and industry trends to predict FDA focus areas, helping you reduce risks before they become compliance problems.

- Regulatory Surveillance: Atlas continuously tracks FDA policy updates, regulatory changes, and inspection outcomes, ensuring organizations stay informed about the latest compliance requirements.

By providing these powerful tools, Atlas Compliance helps businesses address Establishment Inspection Report (EIR) findings efficiently and accurately, ensuring corrective actions are properly implemented and future regulatory issues are avoided.

Conclusion

The FDA Establishment Inspection Report plays a vital role in regulatory compliance. It provides a detailed look at how your operations are evaluated by the FDA and identifies areas that need attention. Failing to act on its findings can lead to repeated citations, enforcement actions, and potential business disruptions.

That’s why adopting a systematic, technology-driven approach to EIR readiness is essential. Atlas Compliance offers all the tools you need, from FDA inspection intelligence and predictive analytics to real-time regulatory surveillance and supplier risk management. By transforming fragmented FDA data into actionable insights, Atlas Compliance enables your organization to stay prepared, compliant, and confident.

Looking to make compliance management easier and stay ready for inspections? Visit Atlas Compliance or Book a Demo to see how our platform can help you stay ahead.

Nice post! 1754822170