Facing an FDA inspection? For businesses in regulated industries such as pharmaceuticals, medical devices, or food production, that moment can define compliance success or expose critical gaps. Long before warning letters are issued, the FDA flags violations through Form 483 observations, formal reports that highlight non-compliance discovered during inspections. In FY 2024 alone, the FDA issued over 4000+ Form 483s, underscoring widespread, repeat violations across sectors.

In this guide, we’ll explore real FDA violation examples pulled from these 483s, so you can understand where companies go wrong. Also, learn how to keep your business audit-ready without scrambling when the inspector arrives. So, let’s get going.

What are FDA Violations?

FDA violations occur when businesses fail to comply with regulations established by the Federal Food, Drug, and Cosmetic Act (FDCA), which the FDA enforces. These violations can range from minor errors in labeling to major failures in product safety or manufacturing processes.

While violations can be unintentional, they still carry significant consequences for organizations, potentially leading to regulatory actions, financial penalties, and harm to public health.

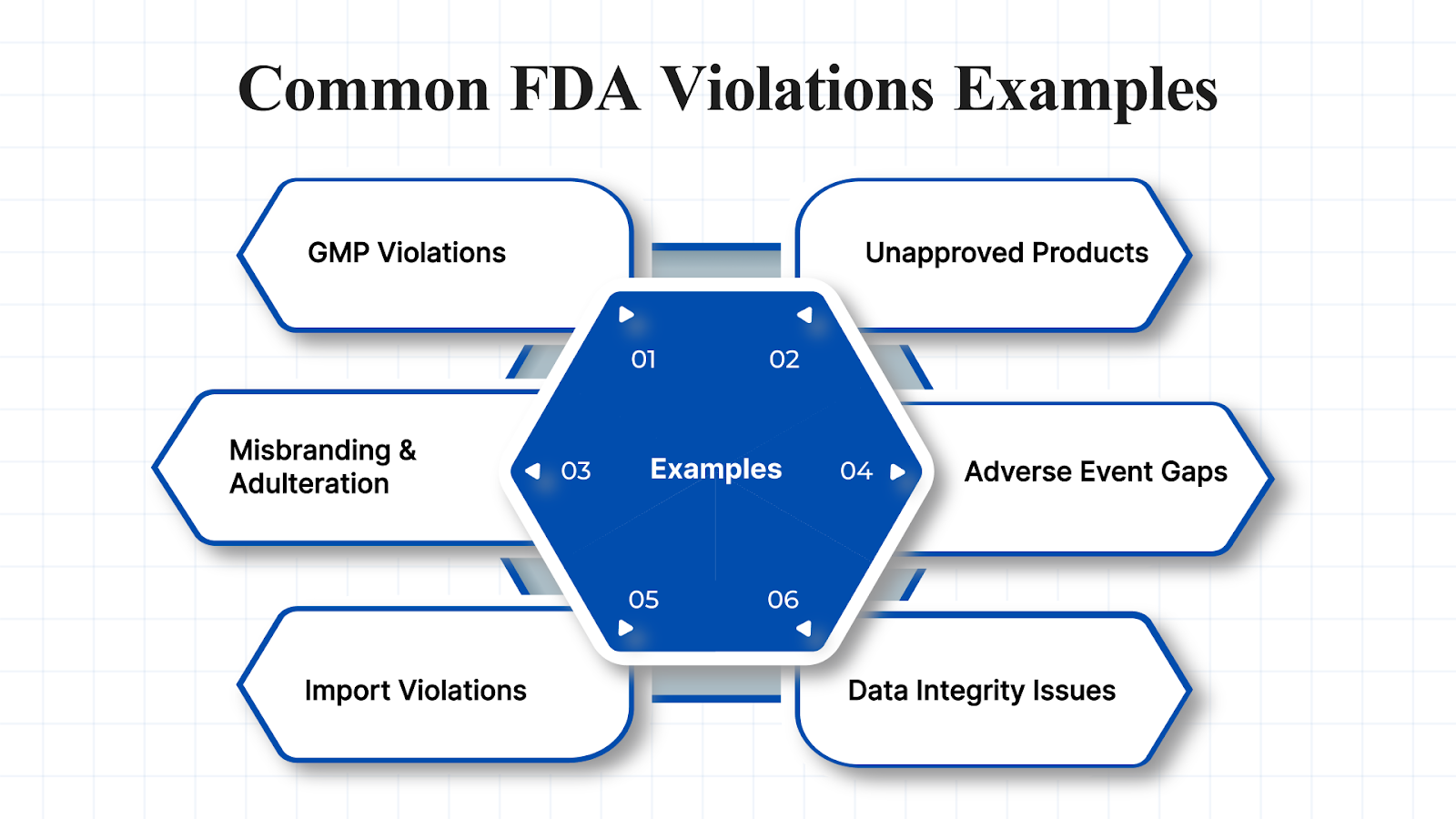

Common FDA Violations Examples

Many FDA violations occur when companies fail to follow regulatory standards that are in place to protect product quality, traceability, and patient safety. Below are key FDA violations examples that businesses across life sciences, pharmaceuticals, and medical devices frequently encounter:

1. Good Manufacturing Practice (GMP) Failures

GMP violations are among the most cited issues during FDA inspections. These violations reflect lapses in how products are manufactured, tested, stored, or handled. Common examples include:

- Improper Aseptic Practices: Risks of contamination due to poor handling of sterile products or inadequate environmental controls.

- Inadequate Documentation: Missing, inconsistent, or poorly maintained records for batch production, quality checks, and complaints.

- Lack of Root Cause Analysis: Failure to thoroughly investigate process deviations or out-of-spec results and neglect to implement CAPA (Corrective and Preventive Actions).

- Facility Shortcomings: Poor maintenance, sanitation problems, pest issues, or ineffective air handling systems that compromise production integrity.

- Neglected Equipment Calibration: Using tools or machinery that are uncalibrated or poorly maintained which can affect the accuracy and consistency of output.

2. Selling Unapproved Drugs or Devices

Marketing products that require FDA pre-market approval without clearance is a serious regulatory offense. This often includes making unauthorized therapeutic claims or bypassing established product registration pathways.

3. Misbranding & Product Adulteration

- Misbranding: This happens when product labels include false claims, omit necessary warnings, or fail to provide proper usage instructions.

- Adulteration: Involves contaminated products, those produced in substandard environments, or those not meeting labeled quality specifications.

4. Adverse Event Reporting Gaps

Medical device and pharmaceutical companies are required to monitor and report serious adverse events, including side effects, safety risks, and product defects. Failure to report in a timely and accurate manner can hinder FDA response and compromise public safety. Common violations include:

- Delayed Side Effect Reporting: Not alerting the FDA promptly about harmful drug reactions.

- Failure to Act on Product Defects: Overlooking or ignoring known defects instead of issuing timely recalls or warnings.

5. Import Compliance Issues

Imported goods must meet the same FDA standards as domestic products. Frequent violations include importing from unapproved sources, mislabeling, or bypassing required customs declarations.

6. Data Integrity Concerns

The FDA closely monitors data management practices. Violations often involve altered, deleted, or manipulated records, especially in electronic systems. Gaps in audit trails and lack of validation for data systems are also common.

These examples highlight how seemingly minor oversights can result in significant regulatory consequences. Addressing them early not only keeps your operations audit-ready but also protects your brand’s reputation and the safety of end users. Spotting issues early helps, but knowing the penalties that follow is just as critical.

What are FDA Warning Letters?

An FDA warning letter is an official notice sent to a company when the agency identifies major compliance issues. Typically, following an inspection, these letters highlight concerns such as goods manufacturing practice (GMP) violations, misbranding, or distribution of unapproved drugs. While not an instant enforcement measure, the letter indicates that the FDA views the issue as significant and anticipates prompt corrective action. Failing to address it can lead to more severe outcomes such as import restrictions, legal injunctions, product confiscation, or even criminal prosecution.

Key 11 FDA Compliance Actions & Penalties

The FDA employs a range of enforcement actions to address non-compliance, escalating in severity based on the nature and risk of the violation.

- Warning and Untitled Letters: Initial notifications highlighting regulatory concerns. Warning Letters indicate significant violations requiring prompt correction, while Untitled Letters address less severe issues.

- Mandatory Recalls: If a product poses health risks and voluntary recall efforts are insufficient, the FDA can mandate a recall to remove the product from the market.

- Notification, Repair, Replacement, or Refund Orders: The FDA may require manufacturers to inform users of defective products and provide remedies, such as repairs, replacements, or refunds, especially when the product poses significant health risks.

- Disqualification of Clinical Investigators or Facilities: Persistent or deliberate non-compliance can lead to the disqualification of individuals or entities from participating in FDA-regulated activities, affecting their ability to conduct or oversee clinical studies.

- Civil Money Penalties: Monetary fines imposed for violations of the Federal Food, Drug, and Cosmetic Act (FDCA). Penalties can be substantial, depending on the severity and number of violations.

- Administrative Detention: The FDA has the authority to temporarily hold products suspected of being adulterated or mislabeled, stopping their distribution pending further review.

- Product Seizure: The FDA has the authority, through a court order, to confiscate products that breach regulations, effectively removing them from the market to protect the public.

- Import Alerts and Embargoes: Products from foreign sources that fail to meet U.S. standards can be refused entry, with import alerts notifying the public and industry of such actions.

- Injunctions: Legal actions that compel a company to cease operations or specific activities until compliance is achieved, often used when other measures fail.

- Criminal Prosecution: In cases of egregious violations, the FDA can pursue criminal charges against individuals or companies, potentially leading to fines and imprisonment.

- Consent Decrees: Legally binding agreements between the FDA and a company outlining specific actions the company must take to correct violations and prevent future occurrences.

Understanding these enforcement mechanisms is crucial for maintaining compliance and making sure that the safety and efficacy of FDA-regulated products. Now that you have comprehended the actions and penalties, let us see the ways to avoid the FDA warning letter.

Notable FDA Violations Cases

The following case studies highlight how some of the most recognized names in healthcare, biotech, and consumer products have come under FDA scrutiny and the lessons every regulated business can learn from their missteps.

1. Ranbaxy Laboratories (2008)

- Violation: FDA inspections revealed serious CGMP violations, including manipulated test data and inadequate quality assurance procedures.

- Outcome: Several Ranbaxy manufacturing facilities were placed under import alert, and the company received multiple warning letters. Although a $500 million settlement was later reached in 2013 for broader violations, this was separate from the 2008 actions.

- Current Status: Ranbaxy was later acquired by Sun Pharmaceuticals, which undertook efforts to address outstanding compliance issues.

- Key Takeaway: Data integrity and strict adherence to manufacturing protocols are essential to avoid escalated enforcement.

2. Theranos (2015)

- Violation: Theranos distributed and used unapproved diagnostic devices, leading to unreliable test results and widespread safety concerns.

- Outcome: The FDA issued warning letters and restricted the use of Theranos devices. The case ultimately led to the company’s shutdown and triggered criminal charges.

- Current Status: The company is defunct. Founder Elizabeth Holmes was convicted of multiple counts of fraud.

- Key Takeaway: Gaining FDA approval before commercializing medical technology is critical; failure to do so can lead to criminal liability and business collapse.

3. Juul Labs (2021)

- Violation: Juul promoted its e-cigarettes with unsubstantiated health claims, positioning them as safer alternatives without FDA authorization.

- Outcome: The FDA intervened, requiring Juul to revise its marketing strategies and submit detailed safety and health data.

- Current Status: Juul remains operational but faces ongoing scrutiny and legal challenges across several jurisdictions.

- Key Takeaway: Health-related marketing claims must be backed by scientific evidence and FDA approval to avoid regulatory backlash.

4. Abbott Nutrition (2022)

- Violation: FDA inspections revealed unsanitary conditions and potential bacterial contamination (Cronobacter sakazakii) at Abbott’s Sturgis, Michigan plant, which produced Similac and other formulas.

- Action Taken: A voluntary recall followed the issuance of a Form 483. The plant was shut down under a consent decree, mandating structural and operational improvements.

- Outcome: The recall contributed to a nationwide formula shortage. Abbott later resumed production under FDA oversight.

- Key Insight: Violations affecting infant health can lead to both regulatory and public backlash.

4. Mylan Laboratories Limited (June 2024)

- Violation: Inspectors uncovered systemic quality control failures, weak lab oversight, and major data integrity violations such as omitted records and manipulated results. Despite identifying issues months earlier, the firm failed to act promptly.

- Regulatory Action: A Warning Letter categorized the products as adulterated. The FDA highlighted concerns over the company’s failure to fully evaluate the scope of non-compliance and implement cultural reforms.

- Current Status: Mylan is expected to deliver a full-scale remediation plan that addresses both procedural and cultural deficiencies.

- Takeaway: Ignoring known data integrity issues and weak investigations damages credibility and invites serious regulatory consequences.

Note: Mylan Laboratories Limited is a Viatris company, and the warning letter is addressed to Viatris, Inc. as the parent company.

5. BEO Pharmaceuticals Inc. (April 2025)

- Violation: An FDA inspection found serious CGMP lapses. These included failure to verify sample identity and conformity, delayed microbial testing, premature product release, and weak supplier qualification processes.

- Regulatory Action: The FDA issued a Warning Letter and advised the firm to consult a CGMP expert. The company must review its material systems and outline corrective measures, including risk assessments for distributed batches.

- Current Status: A formal response outlining corrective and preventive actions is awaited.

- Takeaway: Prompt testing, strong supplier oversight, and a fully functional quality unit are essential for regulatory compliance.

6. Granules India Limited (February 2025)

- Violation: The FDA identified inadequate cleaning and maintenance procedures, visible facility deterioration (notably in AHU ducts), and poor equipment calibration. Data integrity was also questioned due to unclear documentation and staff misinterpretations.

- Regulatory Action: Products were deemed adulterated, and a Warning Letter was issued. The FDA demanded improvements in cleaning validation, equipment management, and data governance. A reminder was issued to inform the Drug Shortages Staff if supply risks arise.

- Current Status: Granules is currently working on corrective actions as mandated by the FDA.

- Takeaway: Facility hygiene, accurate record-keeping, and clear procedural documentation are fundamental to GMP compliance.

These high-profile cases underline a critical truth: no company is immune to FDA enforcement if compliance is overlooked. That’s where Atlas Compliance steps in, not just as a consultant but as a proactive partner, helping you anticipate, address, and prevent regulatory pitfalls before they escalate. Here’s how Atlas can make a tangible difference at every step.

How to Stay Compliant and Avoid Violations

Receiving an FDA warning letter is a serious matter that demands immediate attention. Organizations are generally given 15 working days to submit a written response detailing the corrective actions taken or proposed. But rather than waiting for a warning, let’s explore how to prevent such violations from occurring in the first place:

1. Build a Culture of Quality from Day One

Having transparent processes in place helps prevent compliance slips. This means documenting workflows, regularly reviewing procedures, and creating accountability across teams.

2. Keep Your Team Informed and Prepared

Ongoing training makes sure that your team remains up to date with growing regulatory standards. It’s essential that all employees, from floor operators to supervisors, clearly understand their responsibilities in maintaining compliance.

3. Make Audits a Regular Habit

Don’t wait for the FDA to point out issues. Set up routine internal checks and consider bringing in outside experts for a fresh, unbiased view.

4. Stay Organized with Documentation

Accurate, timely record-keeping is your best defense during an inspection. Maintain clean logs of manufacturing steps, test results, and safety checks.

5. Stay Ahead by Engaging Early

If you’re launching a new product or making process changes, touch base with the FDA early. Proactive communication and swift responses to any feedback can help resolve concerns before they escalate.

Avoiding an FDA warning letter requires discipline, systems, and a proactive mindset, but theory alone isn’t enough. Some of the most valuable lessons in compliance come from real-life cases where avoidable missteps led to significant regulatory fallout. Here’s a look at key FDA warning letter examples and the critical takeaways they offer.

Why Atlas Compliance Is the Right FDA Solution?

Atlas Compliance helps pharmaceutical and MedTech companies stay ahead of FDA scrutiny by simplifying how they manage, monitor, and respond to compliance risks. It’s designed to make inspection readiness and regulatory intelligence more accessible and proactive.

Key benefits include:

- Deep FDA insight: Access historical inspection data, 483s, warning letters, and CFR citations updated weekly.

- AI-powered search: Use NLP tools to find relevant regulatory information without manual digging quickly.

- Predictive risk analysis: Machine learning identifies potential compliance gaps before they become violations.

- Cross-industry coverage: Supports pharma, biologics, food, cosmetics, and more.

- Supplier risk tools: Evaluate and monitor third-party compliance in one place.

- Integrated platform: Bridges the gap between Quality Assurance and Regulatory Affairs.

Atlas Compliance equips your team with the tools to stay compliant, avoid FDA penalties, and build a culture of audit readiness without the guesswork. Schedule a free demo to learn more.

Conclusion

Understanding FDA violations examples goes beyond ticking off compliance requirements; it reveals the critical operational weaknesses that can lead to financial losses and damage consumer trust. Issues like inadequate GMP practices or deceptive product claims underscore the need for robust quality systems, precise documentation, and forward-thinking regulatory strategies.

With the FDA adopting a more data-driven and stringent approach to enforcement, compliance must be treated as a core business priority. Whether you’re preparing for an inspection, assessing suppliers, or launching a new product, learning from past warning letters offers invaluable insight. Partnering with Atlas Compliance can help you stay ahead of potential issues, reduce risk exposure, and make sure that your operations meet growing FDA expectations. Book a demo now to see the change.