Quality Assurance (QA) teams are the silent guardians of compliance in regulated industries. Yet, many organizations overlook the key metrics that reflect not just product quality but regulatory readiness. This article explores essential QA compliance metrics, their strategic value, and how modern tools like Atlas Compliance can bridge the gap between reactive and proactive compliance. Let’s walk through the exact KPIs that transform a QA function from a checkbox activity to a compliance powerhouse.

Why QA Metrics Matter for Compliance

In industries like pharmaceuticals, biotech, medical devices, and food manufacturing, compliance isn’t optional; it’s existential.

The FDA issued more than 12,500 Form 483 observations in 2023, and warning letters rose by 9.6% compared to 2022. Over 72% of these were due to repeat or systemic issues, not isolated events.

These figures underline a hard truth: QA failure isn’t just a quality issue; it’s a business risk.

What Makes a Good QA Metric?

Not all metrics are created equal. Good compliance metrics should be:

- Measurable (quantifiable and objective)

- Actionable (informs decision-making)

- Auditable (traceable with documentation)

- Predictive (signals future risks)

The Top QA Compliance Metrics Every Organization Should Track

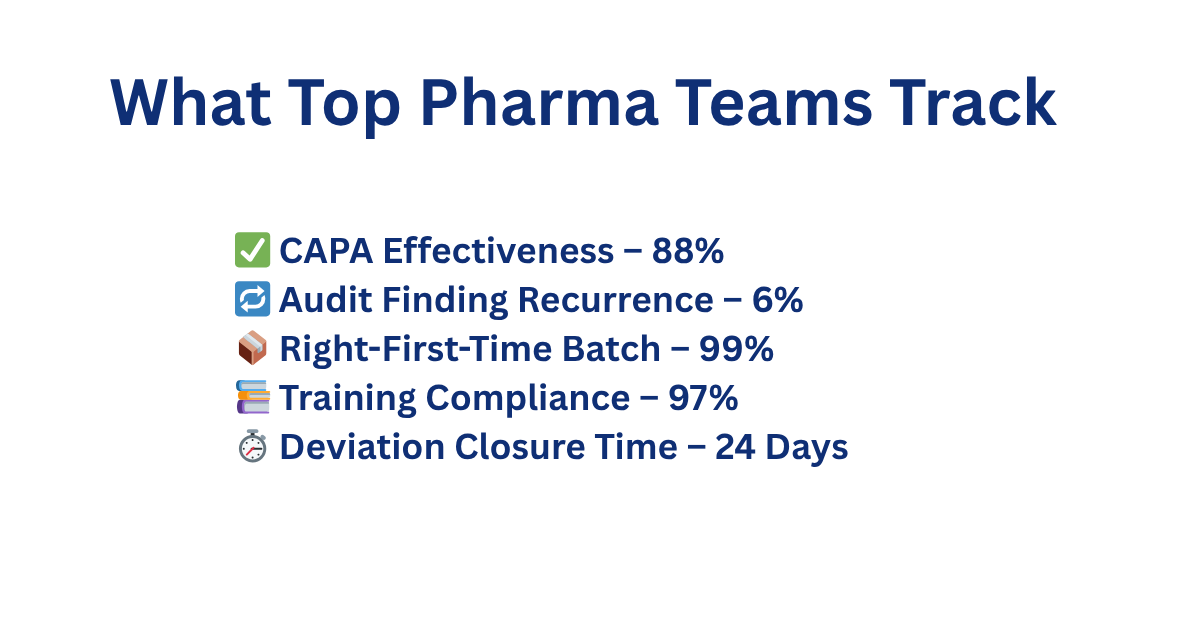

1. CAPA Effectiveness Rate

- Definition: Percentage of CAPAs that are completed, verified, and remain effective after implementation.

- Why It Matters: FDA inspectors often dig deep into CAPAs. A poorly executed CAPA leads to repeat observations.

- Industry Benchmark: Best-in-class organizations report a CAPA effectiveness rate above 85%.

- Atlas Insight: Atlas’s CAPA dashboards let you track root cause linkage and closure timelines to assess real impact, not just task completion.

2. Audit Finding Recurrence Rate

- Definition: Percentage of findings from internal or external audits that reoccur in subsequent audits.

- Goal: <10% recurrence rate

- Problem: A high recurrence rate signals ineffective CAPA implementation or poor root cause analysis.

- Solution: Use trend analytics to map repeat offenders. Atlas provides heatmaps of recurring observations across product lines or facilities.

3. Right-First-Time (RFT) Batch Release

- Definition: Percentage of batches released without any deviation, rework, or QA hold.

- Target: >98%

- Why It’s Critical: Deviations cause delays and trigger FDA scrutiny.

- Real-World Example: One biotech firm increased RFT from 91% to 99.2% after implementing real-time batch review using Atlas.

4. Training Compliance Rate

- Definition: Percentage of QA-relevant employees who completed required training on time.

- Benchmark: >95% completion within due dates

- Common Pitfall: Manual training logs create blind spots. Many companies are cited for insufficient training documentation.

- Atlas Edge: Integrates with LMS platforms to sync data and highlight overdue or expired training certificates.

5. Deviation Closure Time

- Definition: Average number of days to close a deviation from date of detection.

- Industry Standard: ≤30 days for minor, ≤90 days for major deviations

- Why It Matters: Long open deviations suggest systemic risk and slow response culture.

- Solution: Use deviation aging reports to identify backlogs and escalations.

6. Supplier Quality Rating

- Definition: Combines defect rate, audit score, and on-time delivery into a composite score.

- Benchmark: Track % of suppliers scoring above 90.

- Atlas Benefit: Centralizes supplier qualification and nonconformance records, enabling smarter sourcing decisions.

7. Regulatory Inspection Readiness Score

- Definition: Internal score based on mock inspections, SOP adherence, and documentation accessibility.

- Atlas Application: Atlas’ “Pre-Inspection Readiness” module gives a live scorecard based on 483 trends, document availability, and CAPA status.

8. Document Revision Compliance

- Definition: Percentage of SOPs and controlled documents updated within revision cycle time.

- Goal: 100% adherence to change control timelines

- Risk: Outdated SOPs are a frequent FDA 483 topic.

- Tech Assist: Atlas flags documents approaching expiry and tracks review cycle compliance in real time.

9. Complaint Trending and Resolution Time

- Definition: Measures number and nature of product complaints, and average time to resolution.

- FDA Hotspot: Delay in evaluating or addressing complaints can lead to warning letters.

- Data Tip: Use Pareto analysis to identify the top 20% issues causing 80% of complaints.

10. Form 483/Warning Letter Benchmarking

- Definition: Tracks your company’s 483s against industry averages.

- Industry Trend: In 2023, 38% of FDA 483s were related to inadequate quality control units.

- Atlas Power: Atlas houses a database of over 100,000+ Form 483s, giving you instant benchmarking across competitors, regions, or product types.

What Happens When You Don’t Track the Right Metrics?

Let’s be real. Compliance gaps don’t start with catastrophic events—they start with ignored metrics.

🔻 Case Study:

A major pharma firm failed to act on its increasing deviation closure times. The result? An FDA inspection uncovered 78 open deviations, leading to a $10M product hold and global recalls.

Solution:

With Atlas Compliance, this organization implemented automated deviation tracking, integrated with CAPA follow-ups. Within 6 months:

- Deviation closure time dropped from 82 to 27 days.

- Form 483s reduced by 43% year-over-year.

QA Metrics That Predict, Not Just React

Most teams track lagging indicators. But the shift to predictive compliance is underway.

Some emerging metrics:

- AI Risk Scores for Deviations (from historical data)

- Pre-Audit Risk Index (based on SOP status, CAPA history, document readiness)

- Cross-Site Variability Index (compliance gaps across plants)

Atlas is pioneering this movement by feeding your QA metrics into AI models trained on regulatory behavior and inspection trends.

The Role of Atlas Compliance

What makes Atlas different?

- 100,000+ Form 483s and Warning Letters database

- AI co-pilot to prepare for inspections

- Real-time dashboards for CAPA, training, audit findings

- Automated alerts before audit risk escalates

- Benchmarking tools across industry, geography, and facility size

Atlas turns QA from reactive firefighting into proactive compliance leadership.

After 15 years in Quality and Compliance, I can tell you this:

What gets measured gets managed.

And what gets managed… gets approved.

You don’t have to chase compliance. You can lead it if you know what to track.

With evolving regulatory scrutiny and shrinking tolerance for repeat issues, now is the time to empower QA teams with the right metrics and tools like Atlas to move from lagging to leading indicators.

FAQs

Q1. What is the most critical compliance metric for QA teams?

The CAPA effectiveness rate is foundational because ineffective CAPAs often lead to repeat violations and warning letters.

Q2. How often should QA metrics be reviewed?

Ideally monthly, with real-time dashboards reviewed weekly. Annual reviews are too late to fix systemic issues.

Q3. What’s the difference between lagging and leading compliance indicators?

Lagging metrics (e.g., number of 483s) reflect past issues. Leading indicators (e.g., training compliance, SOP update rates) help prevent future problems.

Q4. Can small companies use tools like Atlas?

Yes. Atlas is scalable, from startups to enterprise, offering modular features depending on compliance maturity.

Q5. What metrics are most relevant during FDA inspections?

Training records, deviation handling, CAPA closure, audit history, and document control. These are often the first areas inspectors review.

I take pleasure in, result in I found exactly what I used to be looking for. You have ended my four day long hunt! God Bless you man. Have a great day. Bye